The global energy crunch caused by weather and a resurgence in demand is getting worse, stirring alarm ahead of the winter in 2022.

Mr: Muja added that; At Albanian Minerals we are working to turn an existing crisis into a greatest opportunity, we are looking at the global energy crises and pollution through a different lens, smart plan, creative solutions, right mindset and powerful determination to succeed.

The world has substantial natural resources to solve global problems, pollution , energy crises and demand. With the world’s largest magnesium reserves Albanian Minerals is working 24/7 with top scientist’s and institution around the world.

Today, most of hydrogen is produced using fossil fuel-based processes that together generate more than 2 percent of all global greenhouse gas emissions. In addition, hydrogen is often produced in one location and consumed in another, which means its use also presents logistical challenges and lots of pollution for transportation .

A very promising hydrogen production and storage is under development. Albanian Minerals with collaborations of scientists on the field is working in using magnesium on hydrogen and storage production.

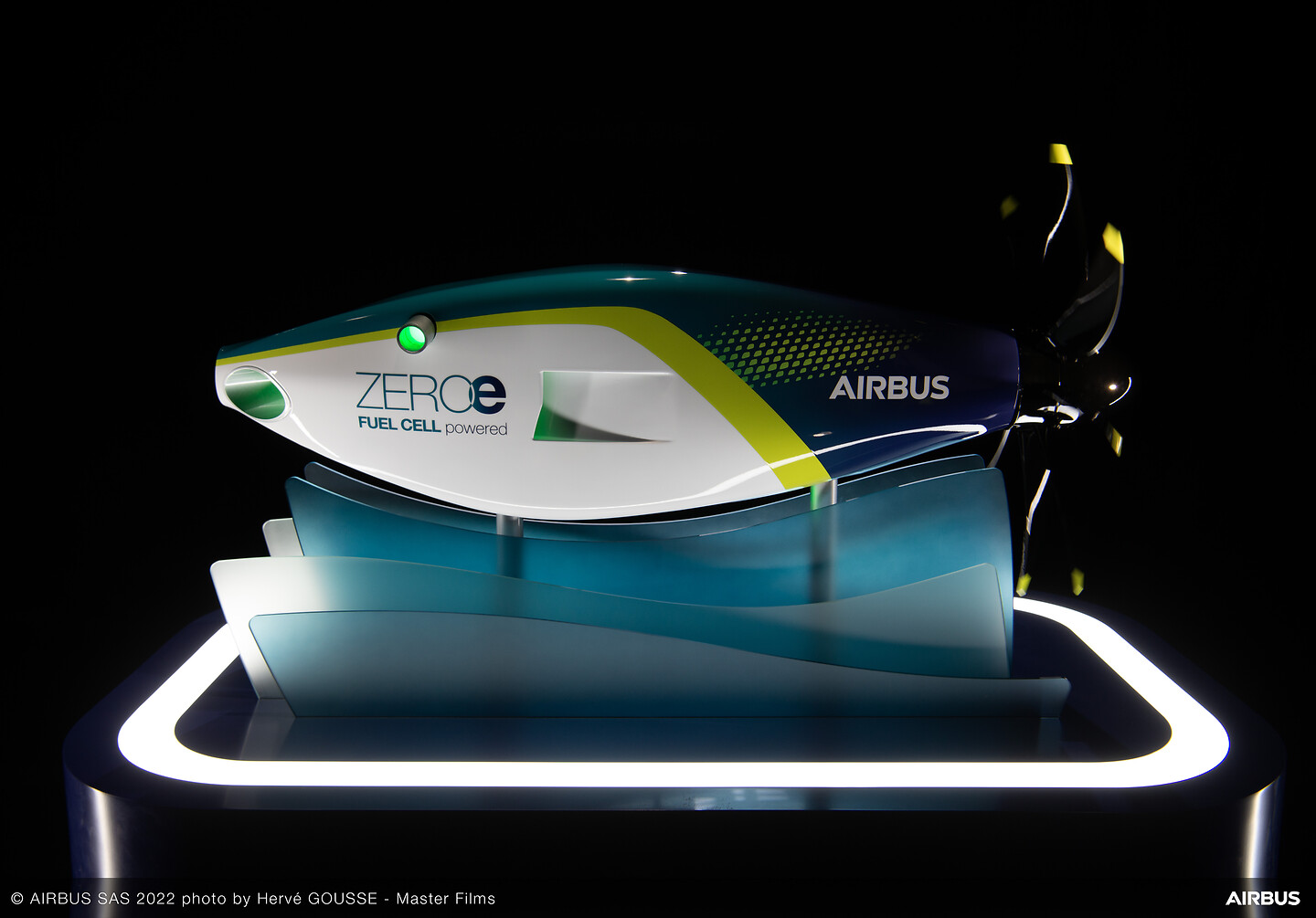

The future of transportation is 100% green, electric and hydrogen mobility. The future of all types of transportation is autonomous driving, the new area of drive autonomously has moved from the realm of science fiction to a very real solution.

The revolutionary breakthrough in science and technology they will continue to shape our lives well into the future.

With the world’s largest magnesium reserves Albanian Minerals is working 24/7 with the best minds in science and entrepreneurship to realize the goals and dreams of a better and greener world.

Producing and storing Hydrogen with Magnesium

ICL Innovation, a technology incubator for ICL, seeks an economically viable carrier material for hydrogen storage and release on demand, based on magnesium hydride. Primary use is in conjunction with hydrogen-bromine regenerative fuel cells. In addition, alternatives to hydrogen gas compression in general applications will be considered.

The producing hydrogen comes from a very fast and reliable reacting of Magnesium with steam or hot water. Magnesium powder metal will readily burns in steam to produce magnesium oxide and hydrogen gas. Magnesium oxide can be re-used with green energy and turn to pure magnesium again , unlimited use, unlimited hydrogen.

Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Dresden have come up with an interesting new way to store and carry hydrogen energy, in the form of a magnesium hydride-based “Powerpaste” that stores the hydrogen in a chemical form, at atmospheric pressure, ready for release when needed.

It has a hydrogen capacity of about 10 mass-% (i.e. 10 kg POWERPASTE → 1 kg hydrogen). This is a specific energy of 1.6 kWh/kg and an energy density of 1.9 kWh/liter—about 10 times the capacity of Li-Ion batteries.

The magnificent Magnesium is revolutionizing entire industries with unmatched strong and light alloys. The aerospace industry has a long history of using magnesium in many applications both civil and military , in the manufacture of aircraft, rockets, and space satellites.

Magnesium is an ideal material : The weight reduction of all industrial products is of high importance, magnesium alloys are the lightest structural alloys

Discover more from Green Innovation News

Subscribe to get the latest posts sent to your email.