According to Chinese National Engineering Research Centre , they have developed supersized magnesium alloy auto parts that could significantly reduce the cost of making cars and promote lightweight vehicle designs. China produce giant car parts using technology similar to Tesla’s ‘gigacasting’ a process that has cut production times and costs. Magnesium alloys could absorb impacts and offer advantages over more common aluminium-based materials, professor says

The scientists produced the two giant parts, a car body and a battery box covers from a single mould in one casting. Each part measures over 2.2 square metres (23.7 sq ft) – the first of their size to be made from magnesium alloy at Research Centre for Magnesium Alloys (CCMg) at Chongqing University.

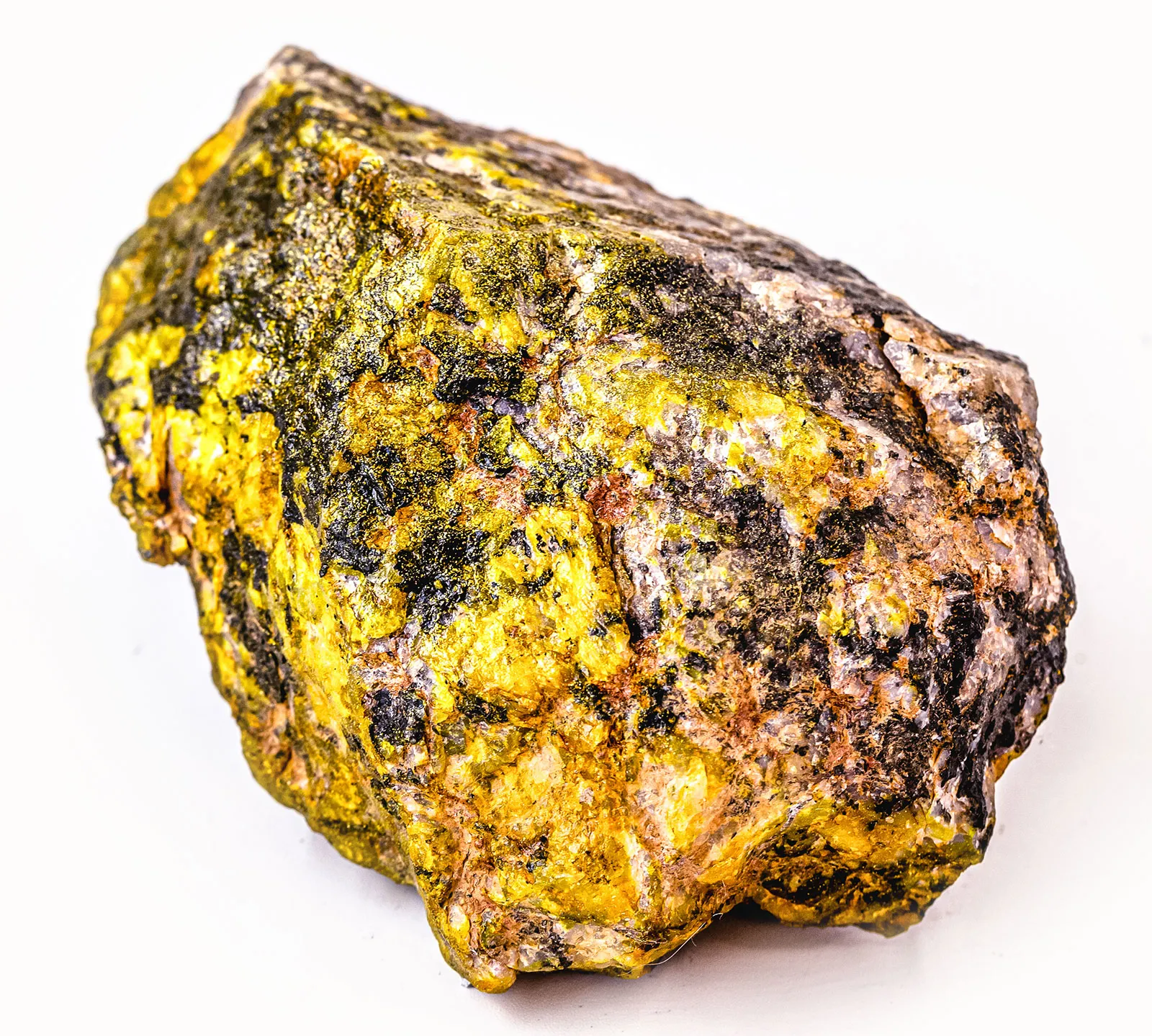

A series of magnesium alloys can be prepared by small additions of metals such as silver, aluminum, cadmium, indium, lead, zinc, yttrium, tin, calcium, manganese, bismuth, cobalt, silicon, and antimony. Magnesium (Mg) is the lightest of structural metals (density of 1.78 kg/dm3, while the specific weight of aluminum is 2.74 kg/dm3).

In general, magnesium alloys exhibit significant specific mechanical strength and are extremely lightweight. Magnesium having a specific weight one-sixth that of steel and one-third that of titanium.

Lightness and robust strength make magnesium an ideal material, vital to the many alloy application.

Magnesium alloys are in use around the world in a variety of different applications. It is a preferred material when looking for weight reduction without compromising overall strength. The vibration damping capacity is also beneficial in applications in which the internal forces of high-speed components must be reduced.

The most common applications are:

- Aircraft and missile components

- Aircraft engine mounts, control hinges, fuel tanks, wings

-

- Automotive wheels, housings, transmission cases, engine blocks

- Bicycles and other sporting goods equipment

- Equipment for material handling

- Ladders

- Laptops, televisions, cell phones

- Luggage

- Portable power tools, chainsaws, hedge clippers, weed whacker, printing and textile machinery, Steering wheels and columns, seat frames

-

Magnesium alloys have also been used as a replacement to some engineering plastics due to their higher stiffness, high recycling capabilities, and lower cost of production.

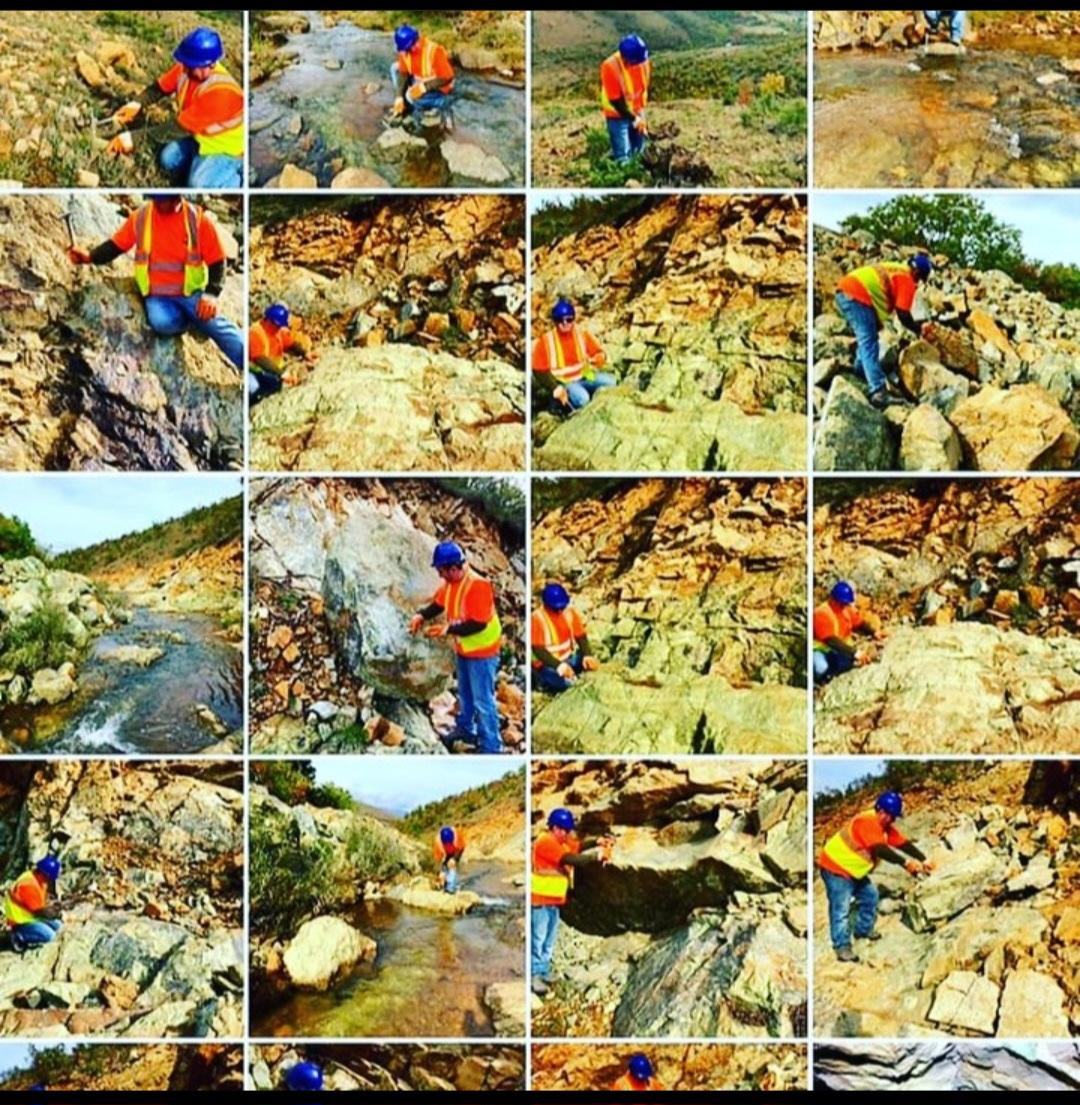

Albanian Minerals holds the world’s largest magnesium reserves.

Sahit Muja Albanian Minerals CEO said, “Magnesium is the next big thing in the 21st century. Engineers and scientists are making major discoveries toward lighter cars, trucks, trains, airplanes, home appliances,vessels, computers, sports gears by developing a way to expand the use of magnesium in parts. Using magnesium sheets to make parts is a significant breakthrough. Magnesium is 75 percent lighter than steel , 50% lighter than titanium, and 33 percent lighter than aluminum”.

Sahit Muja said, “There is unprecedented interest in magnesium, as sources of sustainable supply for new batteries and significantly lighter alloys. Magnesium will profoundly changed the economic outlook of clean energy sources. Also magnesium can be used to producing hydrogen, wind turbines, robots and capturing carbon dioxide.

Albanian Minerals CEO Sahit Muja said, “My strategy to explore magnesium opportunity goes back to a vision which took shape 30 years ago in Albania. As Albanian Minerals CEO, I have begin carving out a forward-thinking strategy to secure world’s largest and best magnesium reserves and leading edge in magnesium production far into the future”.

Mr. Muja added that Magnesium has low density and high strength, magnesium can form high-strength alloy with, chrome aluminum, copper, manganese, nickel, titanium, zinc and other metals as an important alloying element. Currently, China is a major producer and consumer of magnesium in the world. In 2021, China produced near 1 million tons of primary magnesium which was equivalent to 90% of the world’s output.

Sahit Muja said, “There is huge potential to produce Magnesium ore Eco-cements, Magnesium cements absorb CO2 as they set, Magnesium cements can have greater compressive and tensile strength, greater capacity to “breathe” and to bond. Magnesium has the potential to revolutionise the way we capture and convert the CO2 into magnesium carbonate. Scientists has discovered that magnesium bearing minerals has clean the world in beginning from CO2”.