“Revolutionizing Electric Cars: MIT Unveils Sustainable Lithium-Ion Battery, Paving the Way for Cobalt-Free Future”

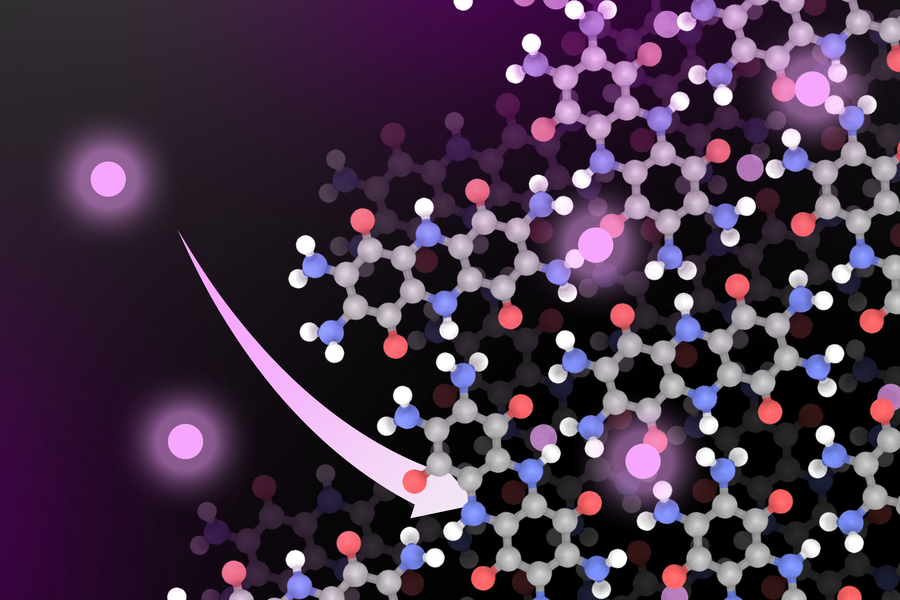

MIT researchers have engineered a groundbreaking lithium-ion battery with an organic-material-based cathode, presenting an eco-friendly alternative to the prevalent use of cobalt in electric vehicles. This innovation promises a more sustainable approach to powering cars, boasting comparable performance to cobalt batteries but at a significantly lower cost.

In a recent study published in ACS Central Science, MIT chemists showcased the newfound battery’s prowess in conducting electricity at rates akin to traditional cobalt batteries. Beyond comparable storage capacity, this lithium-ion battery also offers faster charging capabilities, marking a crucial stride toward minimizing the financial, environmental, and ethical concerns associated with cobalt reliance.

Lead author Tianyang Chen and former MIT postdoc Harish Banda spearheaded the research, emphasizing the material’s potential to reshape the electric vehicle industry. Professor Mircea Dincă, the W.M. Keck Professor of Energy at MIT, highlights the material’s efficiency, stating, “I think this material could have a big impact because it works really well. It is already competitive with incumbent technologies, and it can save a lot of the cost and pain and environmental issues related to mining the metals that currently go into batteries.”

The traditional use of cobalt in batteries poses challenges due to its scarcity, volatile pricing, and association with hazardous mining conditions. MIT’s organic-material-based cathode, developed over six years with Lamborghini’s support, addresses these challenges while maintaining stability and energy density.

The organic material, composed of TAQ (bis-tetraaminobenzoquinone) layers, exhibits remarkable conductivity and storage capacity, rivaling cobalt-containing batteries. Notably, the material’s insolubility prevents degradation over 2,000 charge cycles, surpassing conventional organic battery limitations.

To enhance stability and adherence to the battery’s current collector, the researchers incorporated filler materials like cellulose and rubber. These fillers, comprising a minimal fraction of the cathode composite, extend the battery’s lifespan without significantly compromising storage capacity.

Lamborghini has licensed the patent for this technology, signaling potential adoption in the automotive industry. MIT’s ongoing research aims to further advance alternative battery materials, exploring the replacement of lithium with more abundant and cost-effective options like sodium or magnesium. The breakthrough opens doors to a greener future for electric vehicles, minimizing environmental impact and advancing sustainable energy solutions.

Discover more from Green Innovation News

Subscribe to get the latest posts sent to your email.